Project

Client

Location

Crossfield Excalibur was approached by RBM Ltd and AMRC, to assist in the design and manufacture of a specialist mouldable insert and Sheet Steel tooling to produce an Isotensoid pressure vessel, which would be subject to initial pressures of 350 Bar, and then increasing to 700 Bar.

This was another fascinating project for Crossfield Excalibur to assist in the development of. One that our design department could apply their 25 Years + experience in the Rotomoulding industry.

After an in-depth review of the product requirements and raw material used, PA6 and PA12, an engineered Thermo Plastic Polymer, we set to work designing the tooling and inserts.

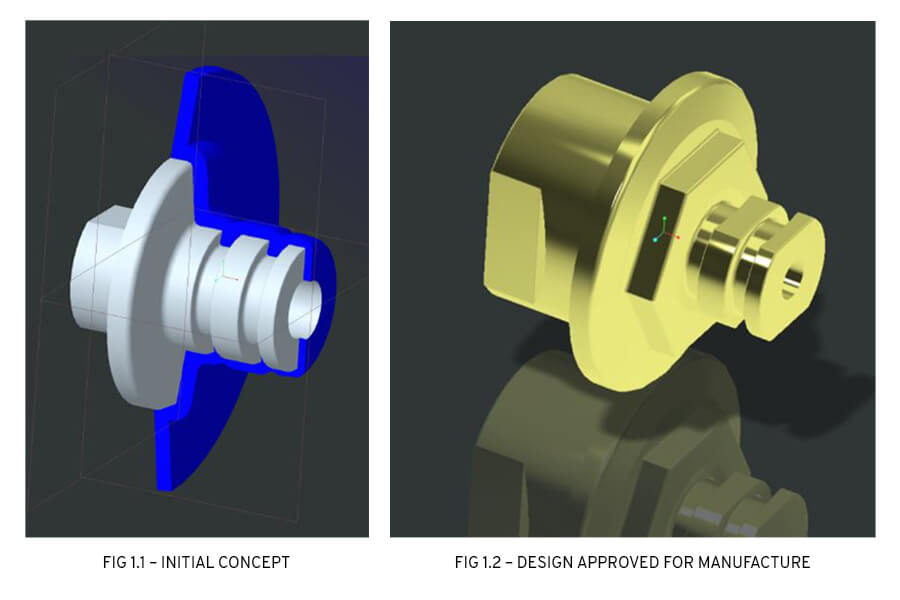

From the initial concept, we came up with various improvements to refine the prototype and achieve an insert that can be manufactured to conform to the following criteria.

First article inspection, Vessel samples were sectioned, to inspect for optimal flow and coverage of the insert. This verified the design had achieved the desired flow levels of polymer.

Mould Tooling and inserts were designed using Creo Parametric 8.0.3.0

The manufacturing data is output in a .stp format, which is then imported into RADAN sheet metal forming software. RADAN is employed to lay a virtual skin on the 3D model, at the required tooling metal thickness. This skin is then extracted and flattened to produce a component that can be laser cut to a highly repeatable tolerance.

Each sheet metal component produced in RADAN has a 2D drawing generated. This forms the basis of a tooling specification document, which is used by the toolmakers to produce the mould. The Isotensoid ends are produced using a CNC spinning machine.

This allows a flat sheet of steel to be formed into a dish shape and form the ends of the mould tool.

Telephone: +44 (0) 161 763 4377

E-mail: in**@ex**********.uk

Crosfield Excalibur Ltd

Unit 21, Woolfold Industrial Estate, Mitchell Street, Bury, Lancs, England, BL8 1SF

Crossfield Excalibur. All Rights Reserved. Website by ATTAIN