Project

Client

Location

A composite hydrogen storage tank has been developed for use in the heavy duty transport sector, supporting supply chains to build their manufacturing capability and to help accelerate the decarbonisation of road transport.

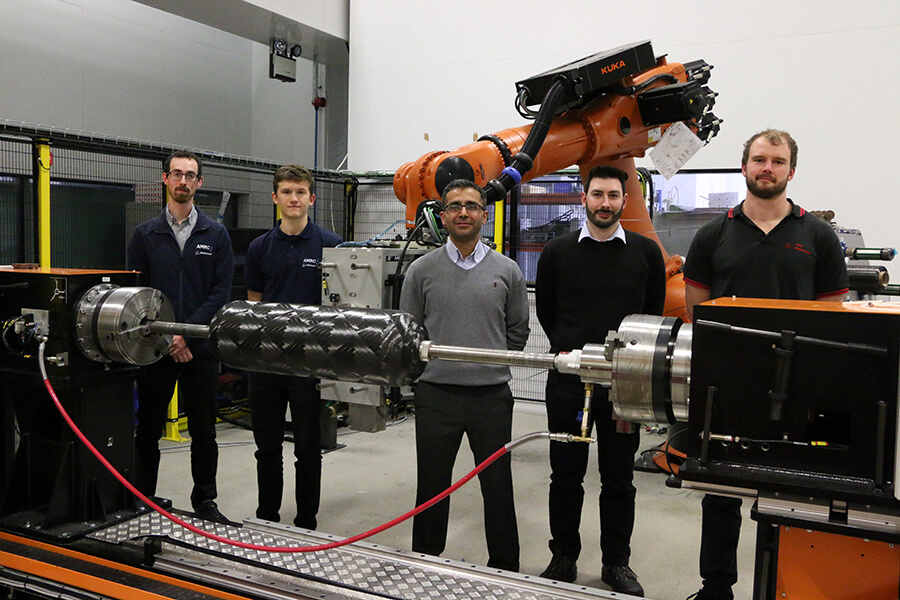

Composites experts from the University of Sheffield Advanced Manufacturing Research Centre (AMRC) worked alongside two SME manufacturers on the 12-month project. The AMRC joined forces with Crossfield Excalibur, a specialist in tooling design for rotationally-moulded parts, and Elite Ground Support Services, which provides rotational, extrusion and compression mouldings for the automotive sector.

Together, they designed, manufactured and tested a Type 4 cylindrical hydrogen pressure vessel, made from filament wound carbon-fibre over a thermoplastic liner. The tank has been designed for use in the automotive sector and has the capacity to hold 40-litres of hydrogen at a 350-bar pressure, with the testing being performed in line with EU regulations.

Investment into the creation of these pressure vessels follows the launch of the government’s net zero and hydrogen strategies and is aimed at supporting the UK to reach net zero emissions by 2050.

The project was funded by the HVM Catapult. The next steps are to continue optimising the designs and the manufacturing process of the pressure vessels, develop testing capabilities further and to increase its storage capacity.

Telephone: +44 (0) 161 763 4377

E-mail: info@excalibur-rm.co.uk

Crossfield Excalibur Ltd

Unit 21, Woolfold Industrial Estate, Mitchell Street, Bury, Lancs, England, BL8 1SF

Crossfield Excalibur. All Rights Reserved.