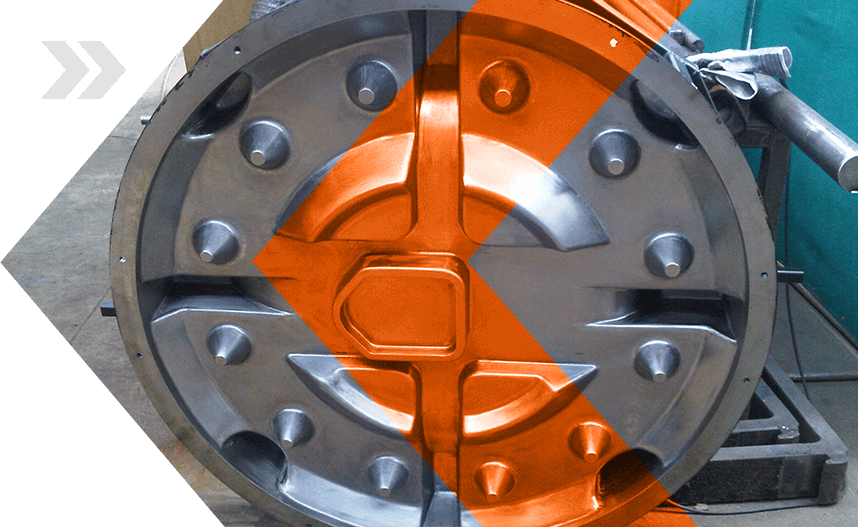

TOOLING

Welcome to Crossfield Excalibur, a leading provider of innovative rotational mould tool making solutions.

With our extensive expertise and advanced manufacturing capabilities, we specialise in designing and producing high-quality moulds that are essential for the roto-moulding process.

Our team of highly skilled engineers combine years of experience and state-of-the-art technologies to deliver precise and reliable moulds that meet the unique requirements of our clients.

From concept to completion, we work closely with our customers, ensuring that every detail is taken into consideration to achieve the desired outcome.

Whether you need moulds for a large-scale production or small custom projects, we are committed to delivering exceptional quality, superior durability, and efficient turnaround times. With a strong focus on innovation and continual improvement, we stay abreast of the latest industry advancements to offer cutting edge solutions that exceed expectations.

Experience the difference with Crossfield Excalibur, your trusted partner for all your rotational mould tool making needs.

Tool Making

There are four different types of tooling most commonly used in Rotational moulding:

- Fabricated Sheet Steel

- Stainless Steel

- Cast Aluminium

- CNC Machined Aluminium

Each type of tooling has it’s own benefits and product design parameters Crossfield Excalibur Ltd specialises in Sheet Steel and Stainless Steel Tooling.

Sheet Steel moulds are one of the moulds most commonly used tools in the Rotational moulding process.