Design Brief:

Create a highly competitive litter bin for a bustling marketplace, boasting a capacious 90-litre capacity.

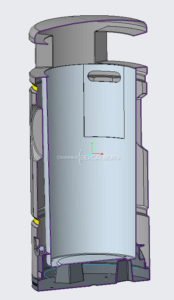

The design features a dome-shaped top with two litter chutes for easy access. The hood is conveniently removable, offering both lock and non-lock options for added versatility. In the absence of a lock, seamless engagement between the hood and base ensures secure positioning.

The choice between a rotomolded or steel liner provides durability and customisation possibilities. The robust rotomolded base offers flexibility with options for ballast or bolt-down configurations. All components are engineered to accommodate recycled powder materials, ensuring sustainability without compromising on quality.

The design journey culminates in a comprehensive CAD presentation, showcasing both 3D and 2D renderings from initial concepts to final approval.

After completing the tooling for the bin, the tool then had a mirror polish applied to elevate the overall aesthetics.

The mages show the internal surface finish of the tool and the finished component which has been expertly moulded and finished to a very high standard.

Tooling is produced in our own steel tooling division from 2mm cr4 ensuring durability and precision.

The blue shimmer on the steel is a result of the heat generated in the ovens during the moulding cycle, a process commonly referred to as annealing. Annealing not only enhances the metal’s ductility but also reduces its hardness, effectively relieving any stresses accumulated during the tooling’s manufacture and welding.